imported PLC control Energy Saving hydraulic JPMX-303SK busbar machine for flat and vertical bending

Production Description:

This series CNC busbar processing machine has three units: punching shearing and bending. It is easy to adjust each unit to shorten the processing time and improve the production efficiency.

The bending unit uses the imported PLC control system, which has a stable system and high precision. It is used to process copper and aluminum busbar in different specification. By relative operation unit it can easily and quickly do all kinds of processing to copper and aluminum busbar, such as shearing, punching(circular hole and oblong hole), flat/Vertical bending and knurling.change different mold to do special processing to copper bar, such as flat press, embossing, cable connector process,and can do cutting,flat crushing pushing and bending.

Function

|

Model

|

JPMX-303CSK

|

JPMX-303SK

|

JPMX-503SK

|

Punching

|

Max.punching force(kn)

|

300

|

300

|

500

|

Punching diameter range(mm)

|

4.3-25

|

4.3-25

|

4.3-30

| |

Max.thickness(mm)

|

12

|

12

|

16

| |

Max.width(mm)

|

160

|

160

|

200

| |

Shearing/Cutting

|

Max.shearing thickness(mm)

|

12

|

12

|

16

|

Max.shearing width(mm)

|

160

|

160

|

200

| |

Horizontal bending

|

Max.bending force(kn)

|

300

|

300

|

500

|

Max.width(mm)

|

160

|

160

|

200

| |

Max.thickness(mm)

|

12

|

12

|

16

| |

Horizontal bending

|

Max.width(mm)

|

100

|

100

|

120

|

Min.angle(Degree)

|

90°

|

90°

|

90

| |

Out dimension

|

mm

|

1780*1380*1420

|

1780*1380*1420

|

1850*1500*1550

|

Power

|

Kw

|

1x4kw

|

3x4kw

|

3*5.5kw

|

Weight

|

Kg

|

1150kg

|

1270kg

|

1950kg

|

CNC precision

|

Bending precision

|

±1

|

±1

|

±1

|

Repeat bending precision

|

±0.5

|

±0.5

|

±0.5

|

Function:

1. Bending at vertical and horizontal direction.

2. Punching for round and oblong hole.

3. Cutting busbar.

4. Special for embossing, knurling, twisting, cable joints pressing.

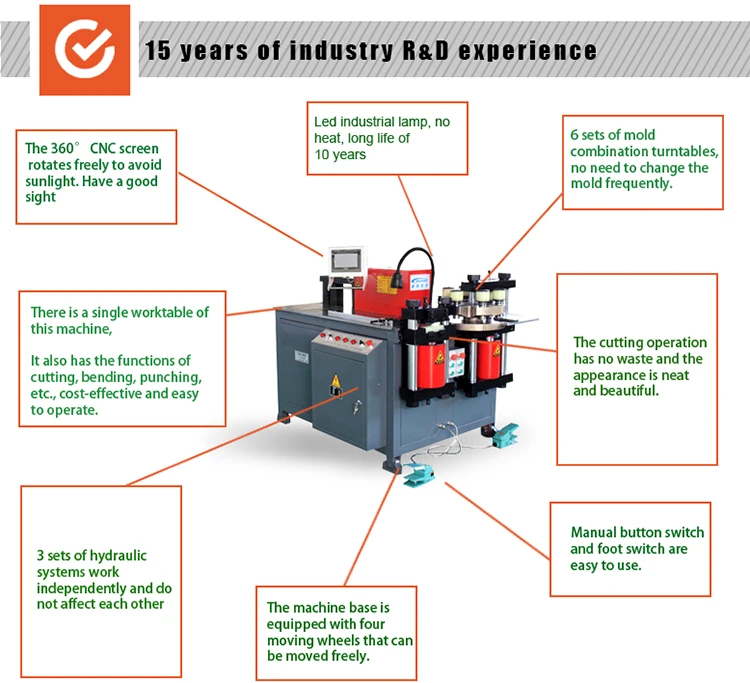

Features:

1. Punching station: Turret punch unit installed with 6 punching dies, no need to change punching dies frequently, save time, reduce die change error, longthen the lifetime of punching dies.

2. Cutting station: two scissors shearing struction. there is no waste busbar generated. The cutting edge is smooth and neat.

3. Bending station: NC control the precision of bending angel. It can bend copper and aluminum busbar in vertical direction and horizontal direction. Through using the customized dies. The bending station can bend copper and aluminum round bars, twisting copper and aluminum flat bars, press cable joint etc.

Processing details

The corner of the workshop

Bending: https://youtu.be/YkcEabcuddg

Cutting: https://youtu.be/bz_RISTiBr4

Punching: https://youtu.be/lI1rU_8ybHY

3 in 1:https://youtu.be/UZgw0l78XG8

Cutting: https://youtu.be/bz_RISTiBr4

Punching: https://youtu.be/lI1rU_8ybHY

3 in 1:https://youtu.be/UZgw0l78XG8

Jingpeng CNC has passed the 15 years of copper bus processing industry R&D, We have established trade relations with more than 100 countries and regions around the world.

Our advantage:

1. Warranty : one year guarantee for whole machine ( not including spare part)

2. Our PLC are from Siemens.

3.Our thermal relays, AC contactors, circuit breakers are from Schneider.

4.We are factory. we can do OEM as per clients request.

5. We have strong after-sales services team and professional technicians who can gurantee professional guidance after sales.

6. With Certification of CE&ISO 9001 .

1. Warranty : one year guarantee for whole machine ( not including spare part)

2. Our PLC are from Siemens.

3.Our thermal relays, AC contactors, circuit breakers are from Schneider.

4.We are factory. we can do OEM as per clients request.

5. We have strong after-sales services team and professional technicians who can gurantee professional guidance after sales.

6. With Certification of CE&ISO 9001 .

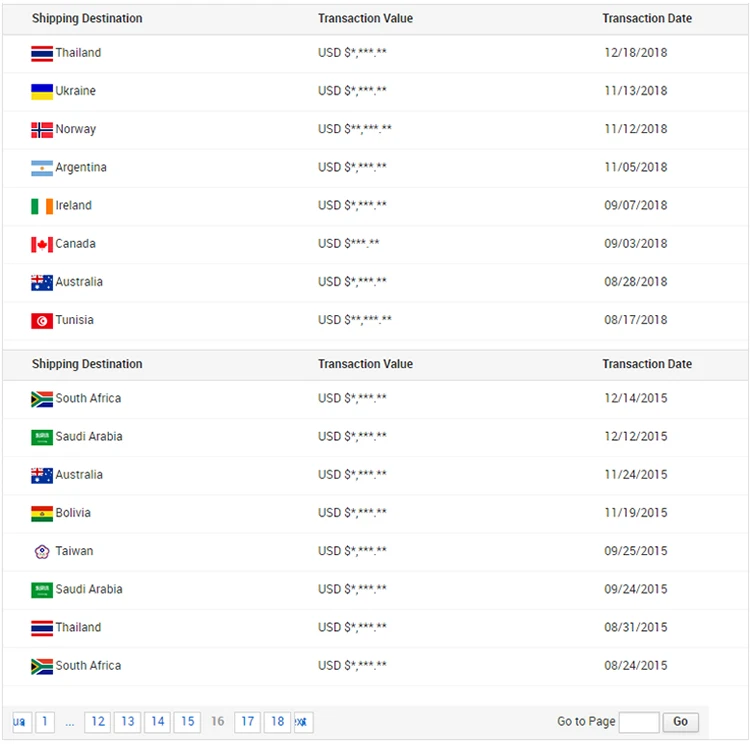

Some record of the transaction by Trade Insurance as follows:

24 hours after-sales service

Waterproof plastic film wrapped inside, wooden cases outside

Our company:

Jinan Jingpeng CNC Machinery Co., Ltd. is a technology company, specializing in the developing, production, selling of electrical & CNC metal plate machines. We have much advanced management experience, strong technology and large selling networks.

FAQ:

1. What is your payment terms?

40% TT as deposit, balance be paid when goods are ready for loading before shipment.

2. What is your delivery time?

Usually within 7-25 days after the deposit.

3. What is your power supply?

We will adjust according to your countries power supply. No problem.

We will adjust according to your countries power supply. No problem.

4. What is your Min order quantity?

One set. Our customers can be end users, retailers and wholesalers.

One set. Our customers can be end users, retailers and wholesalers.

5. Are all the Labels and instructions of the copper hydraulic cnc busbar bending machine in English?

Yes. the labels on the machine and the manuel books are all made in english version.

Yes. the labels on the machine and the manuel books are all made in english version.

6. Besides this copper hydraulic cnc busbar bending machine, do you have any other options for me?

We have dozens of options for you:

CNC busbar machine; Non- CNC busbar machine, combined busbar machine,

busbar cutting tools, busbar bending tools, busbar punching tools.

hydraulic pumps, hand pumps etc.

Please contact with us to know more informations!

We have dozens of options for you:

CNC busbar machine; Non- CNC busbar machine, combined busbar machine,

busbar cutting tools, busbar bending tools, busbar punching tools.

hydraulic pumps, hand pumps etc.

Please contact with us to know more informations!

7. What is your requirement for exclusive / sole agent?

We are looking for sole agent in world market.

We need to test the credit and the monthly quantity of the importers.

If the importer credit is good and reliable. And the monthly order quantity meet local market demand. We will come to further association.

We are looking for sole agent in world market.

We need to test the credit and the monthly quantity of the importers.

If the importer credit is good and reliable. And the monthly order quantity meet local market demand. We will come to further association.

You deserve the best Busbar machining Machine!

没有评论:

发表评论